Kune dzakawanda nzira dzefiriji, uye dzinotevera dzinowanzo shandiswa:

1. Liquid vaporization refrigeration

2. Gasi kuwedzera uye firiji

3. Vortex tube refrigeration

4. Thermoelectric kutonhora

Pakati pavo, liquid vaporization refrigeration ndiyo inonyanya kushandiswa. Iyo inoshandisa kupisa kunyura mhedzisiro yemvura vaporization kuwana firiji. Vapor compression, absorption, mhute jekiseni uye adsorption firiji ese ari mvura vaporization firiji.

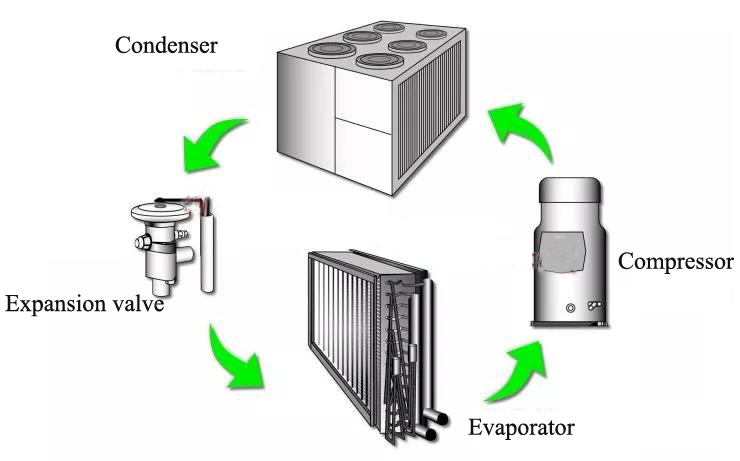

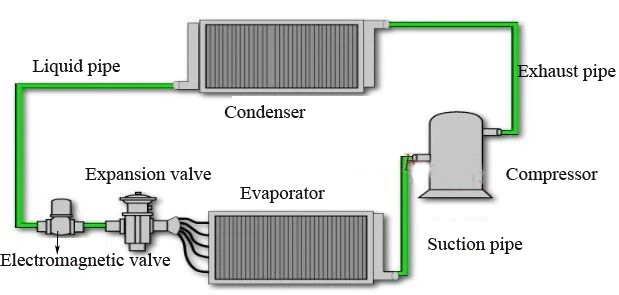

Vapor compression refrigeration ndeyechikamu chekuchinja firiji, iyo inoshandisa kupisa kunyura maitiro kana firiji ichichinja kubva kumvura kuenda kugasi kuti iwane simba rinotonhora. Inoumbwa nezvikamu zvina: compressor, condenser, throttling mechanism uye evaporator. Iwo akabatanidzwa mukutendeuka nemapombi kuti aite yakavharwa system.

Main firiji zvikamu uye accessories

1.Compressor

Compressors yakakamurwa kuita matatu zvimiro: yakavhurika mhando, semi-yakavhurika mhando, uye yakavharwa mhando. Basa recompressor nderekusveta pasi-tembiricha refrigerant kubva kune evaporator side, uye kuimanikidza mumhepo yakakwira-kudzvanywa, yakakwirira-tembiricha refrigerant vapor uye kuitumira kune condenser.

2.Condenser

Iyo condenser mudziyo wekutsinhanisa kupisa unofambisa huwandu hwefiriji hweiyo evaporator mufiriji system pamwe nebasa rekumanikidza recompressor kune svikiro rezvakatipoteredza (mvura inotonhorera kana mweya). Zvinoenderana neinotonhora nzira, iyo condenser inogona kukamurwa kuita mhepo-yakatonhorera, mvura-inotonhorera uye evaporative. Iyo condenser mudziyo wekutsinhanisa kupisa unofambisa huwandu hwefiriji hweiyo evaporator mufiriji system pamwe nebasa rekumanikidza recompressor kune svikiro rezvakatipoteredza (mvura inotonhorera kana mweya). Zvinoenderana neinotonhora nzira, iyo condenser inogona kukamurwa kuita mhepo-yakatonhorera, mvura-inotonhorera uye evaporative.

3. Evaporator

Evaporator zvinoreva kuti mvura yemufiriji inofashaira uye inotora kupisa kwemhepo yakatonhora (mhepo kana mvura) pane tembiricha yakaderera kuti iite chinangwa chefiriji.

4. Solenoid valve

Solenoid valve imhando yevhavha yekuvhara iyo inovhurwa otomatiki pasi pesimba remagetsi. Iyo inowanzoiswa pane pombi yehurongwa kuti ishandure otomatiki nekudzima iyo actuator yembiri-nzvimbo regulator yefiriji system pombi. Iyo solenoid valve inowanzoiswa pakati pevhavha yekuwedzera uye condenser. Nzvimbo yacho inofanirwa kunge iri padhuze nepazvinogona nevhavha yekuwedzera, nekuti vharafu yekuwedzera ingori chinhu chinotenderedza uye haigone kuvharwa yega, saka solenoid valve inofanirwa kushandiswa kucheka pombi yekupa mvura.

5.Thermal kuwedzera valve

Zvigadzirwa zvefiriji zvinowanzoshandisa mavharuvhu ekuwedzera ekupisa kugadzirisa kuyerera kwefiriji. Haisi iyo chete yevhavha inogadzirisa iyo inodzora mvura inopihwa evaporator, asiwo iyo throttle valve yefiriji mudziyo. Ivhavha yekuwedzera yekupisa inoshandisa shanduko mune yakanyanya kupisa yefiriji pakubuda kweiyo evaporator kugadzirisa mvura inopihwa. Ivhavha yekuwedzera inopisa yakabatana kune pombi yemvura inopinza ye evaporator, uye tembiricha inonzwa girobhu inoiswa pane evaporator outlet (outlet) pombi. Inowanzo kupatsanurwa kuita zvimiro zvakasiyana zvinoenderana nechimiro cheiyo thermal yekuwedzera valve:

(1) Mukati kuenzanisa thermal kuwedzera valve;

(2) Kunze kwakadzikama kupisa kwevhavha yekuwedzera.

Mukati yakaenzana yemafuta ekuwedzera vharafu: Inoumbwa negirobhu inonzwa tembiricha, capillary chubhu, chigaro chevharuvhu, diaphragm, ejector tsvimbo, valve tsono uye kugadzirisa maitiro. Mavharuvhu ekuwedzera emukati akaenzana anowanzo kushandiswa mune zvidiki evaporator.

Externally balanced thermal expansion valve: External balanced thermal expansion valve For evaporators ane mapaipi akareba kana kupikisa kukuru, mavharuvhu ekuwedzera ekuwedzera ekunze anowanzoshandiswa. Kune evaporator yehukuru hwakafanana, mukati mukati mekuwedzera kwevhavhavhavha yekuwedzera inogona kushandiswa kana yakashandiswa mukuchengetedza kwekushisa kwepamusoro, nepo kunze kwekunze kwevhavha yekuwedzera inogona kushandiswa kana ichishandiswa munzvimbo yakadzika-yekudzivirira. Kune evaporator yehukuru hwakafanana, mukati mukati mekuwedzera kwevhavhavhavha yekuwedzera inogona kushandiswa kana yakashandiswa mukuchengetedza kwekushisa kwepamusoro, nepo kunze kwekunze kwevhavha yekuwedzera inogona kushandiswa kana ichishandiswa munzvimbo yakadzika-yekudzivirira.

6. Muparadzi wemafuta

Muparadzi wemafuta anowanzo kuiswa pakati pecompressor uye condenser kuti aparadzanise mafuta emuchina wefiriji akaiswa muhutsi hwefiriji. Chishandiso chekudzorera mafuta chinoshandiswa kudzosera mafuta emuchina wefiriji kune crankcase yecompressor; iyo inowanzoshandiswa chimiro cheanoparadzanisa oiri ine marudzi maviri: centrifugal mhando uye sefa mhando.

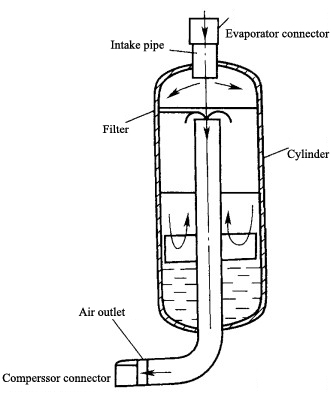

7. Gasi-mvura yekuparadzanisa

Kuparadzanisa gasi refrigerant kubva kune refrigerant yemvura kudzivirira compressor kubva kune nyundo yemvura; chengetedza refrigerant liquid mufiriji cycle, uye gadzirisa mvura yemvura maererano nekuchinja kwemutoro.

8. Dzimba

Nekumisa iyo accumulator, iyo yekuchengetera mvura yeaccumulator inogona kushandiswa kuenzanisa uye kudzikamisa kutenderera kwefiriji muhurongwa, kuitira kuti mudziyo wefiriji uri mukushanda kwakajairika. Iyo accumulator inowanzoiswa pakati pe condenser uye throttling element. Kuti refrigerant yemvura iri mu condenser ipinde mu accumulator zvakanaka, nzvimbo ye accumulator inofanira kunge yakaderera pane condenser.

9. Dryer

Kuti uve nechokwadi chekutenderera kwakajairika kwefiriji, iyo firiji system inofanirwa kuchengetwa yakachena uye yakaoma. Iyo sefa yekuomesa inowanzoiswa pamberi peiyo throttling element. Kana iyo refrigerant yemvura yatanga kupfuura nepafiriji yekuomesera, inogona kudzivirira kuvharika mukati meiyo throttling element.

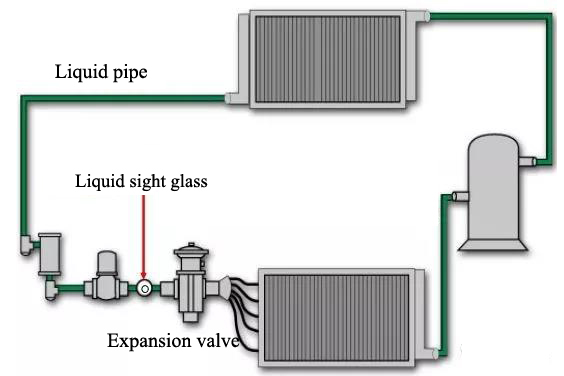

10. Girazi rekuona

Inonyanya kushandiswa kuratidza mamiriro efiriji mupombi yemvura yemuchina wefiriji uye zvinyorwa zvemvura mufiriji. Kazhinji, mavara akasiyana-siyana akaiswa pachiitiko chegirazi rekuona kuratidza huwandu hwemvura yefiriji muhurongwa.

11. Yakakwirira uye yakaderera voltage relay

Kana iyo compressor discharge pressure yakanyanya kukwira, inozodzima, kumisa compressor uye kubvisa chikonzero cheiyo yakanyanya kudzvanywa, uyezve nemaoko reset kuti utange compressor (fault + alarm); kana suction pressure inodonha kusvika pazasi pemuganho, inozodzima. Misa iyo compressor, uye simbisa iyo compressor zvakare kana suction pressure ichikwira kusvika kumusoro.

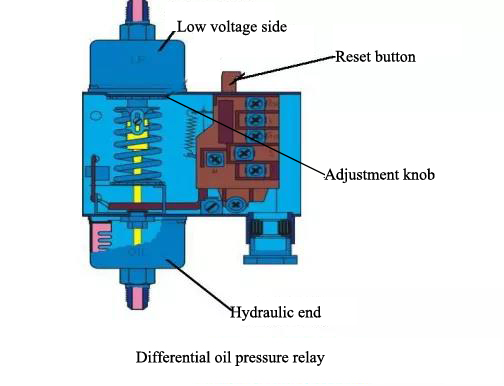

12. Yakasiyana oiri pressure relay

Shanduko yemagetsi inoshandisa mutsauko wepakati pakati pekusveta uye kubuda kwepombi yemafuta ekuzora sechiratidzo chekudzora, kana mutsauko wekumanikidza uri pasi peiyo yakatarwa kukosha, inomisa compressor kuti idzivirire.

13. Tembiricha relay

Shandisa tembiricha sechiratidzo chekudzora kudzora tembiricha yekuchengetera inotonhora. Kutanga uye kumira kwecompressor kunogona kudzorwa zvakananga nekudzora iyo uye kubva kune yemvura inopa solenoid valve; kana muchina mumwe uine akawanda mabhanga, tembiricha inodzoreredza yebhangi rega rega inogona kubatanidzwa mukufanana kudzora otomatiki kutanga uye kumira kwe compressor.

14. Refrigerant

Mafiriji, anozivikanwawo semafiriji uye mafiriji, zvinhu zvemidhiya zvinoshandiswa mumajini akasiyana siyana ekupisa kupedzisa kutendeuka kwesimba. Zvinhu izvi zvinowanzo shandisa shanduko yechikamu chinodzoreredzwa (sekuchinja kwegasi-mvura) kuwedzera simba.

15. Mafuta efiriji

Basa refiriji muchina mafuta rinonyanya kuisa mafuta, chisimbiso, kutonhorera uye kusefa. Mune akawanda-cylinder compressors, mafuta ekuzora anogona zvakare kushandiswa kudzora nzira yekuburitsa.

Nguva yekutumira: Nov-15-2021